ALUMINISING (Astronomical) & OPTICAL TESTING

Although this price list is specifically for astronomical mirrors we are happy to undertake the re-coating of any optical component as may be used in:

- Car H U D mirrors

- Printing or copy machines

- Projection mirrors

- Parabolic projector mirrors

- Collimators

We are willing to undertake the re-coating of any optical component!

We also provide a re-coating service for sextant mirrors, camera mirrors and prisms. For prices please go to our

Sextant and Camera Mirrors page or click

HERE

Mirrors for recoating can often look as bad as this before re-aluminising!

Aluminising Information

Prices quoted for mirrors up to 12 inches (310 mm) in diameter are for double

aluminising and silicon over-coating. Please state clearly with your order if

you do not require your mirror to be over-coated (there is no price difference).

If your mirror is being sent for re-coating, there is no charge for the removal

of the old aluminium coat. Only in very rare circumstances would a telescope

user choose an unprotected aluminium coating. There would be a three to four

percent gain in light reflection, peaking towards the blue end of the spectrum.

However, unless stored for many months to develop a natural surface hardness

(oxidisation) the coating would probably degrade very quickly in present day

atmospheric conditions.

What does double aluminising entail as mirrors are

usually only given one coating?

Once the mirror is clean and ready to coat it is

given a semi (not totally opaque) aluminium coating and overcoating. It is

then taken out of the chamber and cleaned with a pure cotton cloth and isopropyl

alcohol. This ensures the removal of any poorly adhering particles in the

aluminium coating and toughens the surface. It is then returned to the chamber

and given a second aluminium coating and overcoating. This double coating

is therefore aimed at giving the mirror as long an observing life as possible

with maximum immediate protection from atmospheric pollution.

Mirrors larger than 12 inches 300 mm) diameter are given a single coating

and overcoating in our larger chamber(s) with evaporation from multiple evaporation

points. This partly mimics the double coating of the smaller mirrors. A complete

double coating process can be carried out for these larger mirrors, but with

a sixty percent increase in cost. If you are working within a budget and do

not require maximum double coating protection as offered for the smaller mirrors,

a standard single coating run is available at a 25 percent reduction.

How long will a protected aluminium coating last?

If subjected to sea water, or sulpherous fumes, perhaps

only a few days. If used close to the sea or in an industrial area and stored

uncovered, perhaps only a year. With a close fitting, acid free cover over

the mirror, in the same circumstances perhaps two or three years. Used in

averagely polluted air (everywhere?) with a close fitting cover, perhaps four

to eight years. One way, however, to make sure you ruin the coating is to

wrap it tightly in polothene or plastic to trap in all the pollution and condensation

when not in use!

Can the coating be cleaned?

Yes.Cleaning is possible with mirrors other than plastic. We supply basic

cleaning advice with mirrors.Six months or longer after coating, correct cleaning

should toughen and harden the coating for a longer life.

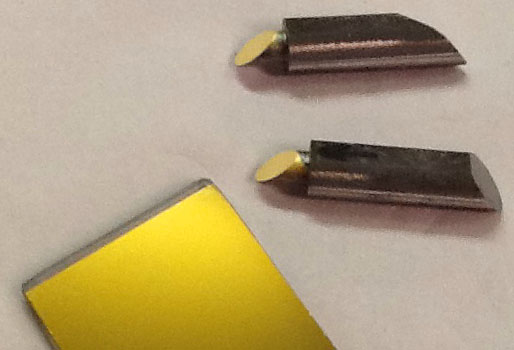

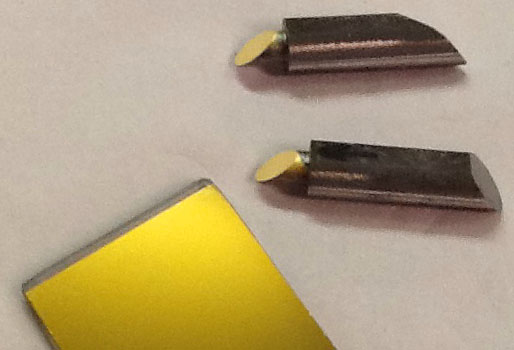

An example of our gold coatings

An Audi heads-up display before and after re-mirroring

Aluminising Prices